Archive for November 2010

Working of Six Stroke Engine

You might be thinking this that i've gone mad, but a man naming Bruce Crower did so. And you know what he got, he got an addition two stroke which not only improves efficiency of the engine by 40% but also reduces pollution.

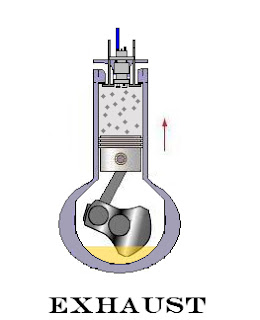

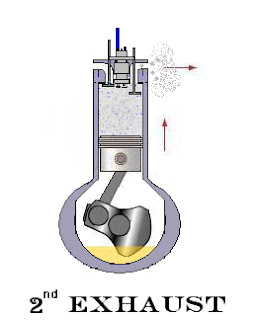

Actually the engine starts with an regular Otto cycle or 4-stroke cycle delaying the 5th and the 6th stroke. Once the engine's temperature reaches 204.44 degree C water is induced in the cylinder after the Exhaust stroke or the fourth stroke. Water expand to 1600 times its volume and forces the piston down for an additional stroke and thus an extra power stroke adds up giving extra benefit to the engine. This type of engine don't want an cooling system because the water based cooling system has added an extra power stroke to the engine. Now we all know water is an renewable resource hence after the water based power stroke, this water is collected back by a condenser attached with the exhaust pipe. Hence this water can be used up again as a fuel for 5th and 6th stroke.

Let's understand it better via a Diagram:

2nd Power Stroke: This is the stroke where water is injected inside the engine so that it pushes the piston down. Hence an extra power stroke has been added which would again provide more power with better efficiency.

Actually there are various proposed 6 stroke engine but currently notable designs in this class are the Crower six-stroke engine, invented by Bruce Crower of the U.S. which we have learned; the Bajulaz engine by the Bajulaz S.A. company of Switzerland; and the Velozeta Six-stroke engine built by the College of Engineering, at Trivandrum in India.

Nov 28, 2010

Posted by Sayantan Mandal

How Turbocharger Works

Turbocharges and Supercharges are one of my favorite topics to talk about, these are one of the greatest engineering marvelous of its kind.

First of all let's talk about what Turbocharges

Actually both of them work on the same principle, both of them uses the same mechanism to work the only difference lies on the power source they both uses. Lets firstly talk about what is Turbochargers.

Turbocharges are a type of a forced induction system. It forces the flowing air into the engine or the combustion chamber without significantly effecting the the weight of the engine. Now the availability of the air inside the chamber is more, hence more fuel can be used and as a result we get a large boost per explosion. (READ- How car engine works to get familiar to these words.)

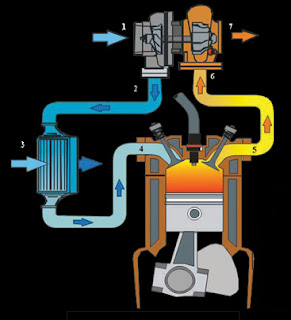

Turbocharges are just like turbines used in Dams to convert the heavy flow of water into rotational motion. In case of Turbocharges the fast flow of the exhaust gases via exhaust pipe is used up in rotating the turbocharges or turbine blades. Now here the blades pushes the fresh air into the intake port. The air is highly compressed and reaches the engine via inter-coolers in order to avoid knocking.

Let's understand with the help of a simple diagram of a typical Turbo Charger----

Key to the Diagram:

5- Exhaust is leaving the chamber

6- It reaches the Turbo Charger

7- Exhaust is leaving the Turbocharger with high speed as a result it rotates the blades of the other end of the other end of the Turbocharger

1- Air is sucked in due to pressure created by the rotation of the blades

2- Compressed is taken to Inter-cooler

3- Air is cooled in the Inter-cooler

4- It reaches the Intake port

Just think about it once that if you install a small turbine which can increase your car performance by 60-70%. It can achieve a spinning rate of 2,500 rps which is 30-40 times faster than most car engine.

Amazing isn't it....

First of all let's talk about what Turbocharges

Actually both of them work on the same principle, both of them uses the same mechanism to work the only difference lies on the power source they both uses. Lets firstly talk about what is Turbochargers.

|

| Di-section View of Turbocharges |

Turbocharges are just like turbines used in Dams to convert the heavy flow of water into rotational motion. In case of Turbocharges the fast flow of the exhaust gases via exhaust pipe is used up in rotating the turbocharges or turbine blades. Now here the blades pushes the fresh air into the intake port. The air is highly compressed and reaches the engine via inter-coolers in order to avoid knocking.

|

| Labeled Diagram of Turbocharger's parts |

Let's understand with the help of a simple diagram of a typical Turbo Charger----

Key to the Diagram:

5- Exhaust is leaving the chamber

6- It reaches the Turbo Charger

7- Exhaust is leaving the Turbocharger with high speed as a result it rotates the blades of the other end of the other end of the Turbocharger

1- Air is sucked in due to pressure created by the rotation of the blades

2- Compressed is taken to Inter-cooler

3- Air is cooled in the Inter-cooler

4- It reaches the Intake port

Just think about it once that if you install a small turbine which can increase your car performance by 60-70%. It can achieve a spinning rate of 2,500 rps which is 30-40 times faster than most car engine.

Amazing isn't it....

Nov 26, 2010

Posted by Sayantan Mandal

Basic concepts or Defination

In order to understand knocking we have to clear a few basic concepts about gases. Now we know that-

PV = nRT, where P = pressure, V = volume, n = mole, R = gas constant, T = temperatureFrom the above formula we come to know that pressure and volume is directly proportional to temperature-let we have taken 1 mole of gas and constant can be ignored. When we reduce the volume of gas or compress it -or apply pressure to gas- then temperature of gas would increase.

If temperature of the gas on reaching the combustion chamber is high enough for the gas to burn, then the gas inside the combustion chamber would burn before the ignition of the spark plug. This phenomena is called Knocking. Knocking can seriously damage an engine!