Data Analysis – How to use

-

Today, I came across a very interesting article and I am very excited to

share it with all of you. Please read the article below and comment your

thoughts....

Archive for 2010

Working of Six Stroke Engine

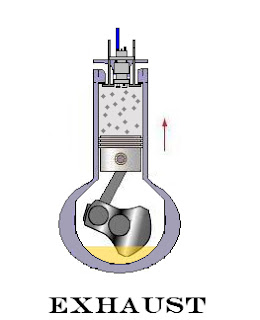

You might be thinking this that i've gone mad, but a man naming Bruce Crower did so. And you know what he got, he got an addition two stroke which not only improves efficiency of the engine by 40% but also reduces pollution.

Actually the engine starts with an regular Otto cycle or 4-stroke cycle delaying the 5th and the 6th stroke. Once the engine's temperature reaches 204.44 degree C water is induced in the cylinder after the Exhaust stroke or the fourth stroke. Water expand to 1600 times its volume and forces the piston down for an additional stroke and thus an extra power stroke adds up giving extra benefit to the engine. This type of engine don't want an cooling system because the water based cooling system has added an extra power stroke to the engine. Now we all know water is an renewable resource hence after the water based power stroke, this water is collected back by a condenser attached with the exhaust pipe. Hence this water can be used up again as a fuel for 5th and 6th stroke.

Let's understand it better via a Diagram:

2nd Power Stroke: This is the stroke where water is injected inside the engine so that it pushes the piston down. Hence an extra power stroke has been added which would again provide more power with better efficiency.

Actually there are various proposed 6 stroke engine but currently notable designs in this class are the Crower six-stroke engine, invented by Bruce Crower of the U.S. which we have learned; the Bajulaz engine by the Bajulaz S.A. company of Switzerland; and the Velozeta Six-stroke engine built by the College of Engineering, at Trivandrum in India.

Nov 28, 2010

Posted by Sayantan Mandal

How Turbocharger Works

Turbocharges and Supercharges are one of my favorite topics to talk about, these are one of the greatest engineering marvelous of its kind.

First of all let's talk about what Turbocharges

Actually both of them work on the same principle, both of them uses the same mechanism to work the only difference lies on the power source they both uses. Lets firstly talk about what is Turbochargers.

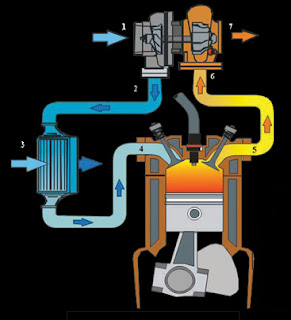

Turbocharges are a type of a forced induction system. It forces the flowing air into the engine or the combustion chamber without significantly effecting the the weight of the engine. Now the availability of the air inside the chamber is more, hence more fuel can be used and as a result we get a large boost per explosion. (READ- How car engine works to get familiar to these words.)

Turbocharges are just like turbines used in Dams to convert the heavy flow of water into rotational motion. In case of Turbocharges the fast flow of the exhaust gases via exhaust pipe is used up in rotating the turbocharges or turbine blades. Now here the blades pushes the fresh air into the intake port. The air is highly compressed and reaches the engine via inter-coolers in order to avoid knocking.

Let's understand with the help of a simple diagram of a typical Turbo Charger----

Key to the Diagram:

5- Exhaust is leaving the chamber

6- It reaches the Turbo Charger

7- Exhaust is leaving the Turbocharger with high speed as a result it rotates the blades of the other end of the other end of the Turbocharger

1- Air is sucked in due to pressure created by the rotation of the blades

2- Compressed is taken to Inter-cooler

3- Air is cooled in the Inter-cooler

4- It reaches the Intake port

Just think about it once that if you install a small turbine which can increase your car performance by 60-70%. It can achieve a spinning rate of 2,500 rps which is 30-40 times faster than most car engine.

Amazing isn't it....

First of all let's talk about what Turbocharges

Actually both of them work on the same principle, both of them uses the same mechanism to work the only difference lies on the power source they both uses. Lets firstly talk about what is Turbochargers.

|

| Di-section View of Turbocharges |

Turbocharges are just like turbines used in Dams to convert the heavy flow of water into rotational motion. In case of Turbocharges the fast flow of the exhaust gases via exhaust pipe is used up in rotating the turbocharges or turbine blades. Now here the blades pushes the fresh air into the intake port. The air is highly compressed and reaches the engine via inter-coolers in order to avoid knocking.

|

| Labeled Diagram of Turbocharger's parts |

Let's understand with the help of a simple diagram of a typical Turbo Charger----

Key to the Diagram:

5- Exhaust is leaving the chamber

6- It reaches the Turbo Charger

7- Exhaust is leaving the Turbocharger with high speed as a result it rotates the blades of the other end of the other end of the Turbocharger

1- Air is sucked in due to pressure created by the rotation of the blades

2- Compressed is taken to Inter-cooler

3- Air is cooled in the Inter-cooler

4- It reaches the Intake port

Just think about it once that if you install a small turbine which can increase your car performance by 60-70%. It can achieve a spinning rate of 2,500 rps which is 30-40 times faster than most car engine.

Amazing isn't it....

Nov 26, 2010

Posted by Sayantan Mandal

Basic concepts or Defination

In order to understand knocking we have to clear a few basic concepts about gases. Now we know that-

PV = nRT, where P = pressure, V = volume, n = mole, R = gas constant, T = temperatureFrom the above formula we come to know that pressure and volume is directly proportional to temperature-let we have taken 1 mole of gas and constant can be ignored. When we reduce the volume of gas or compress it -or apply pressure to gas- then temperature of gas would increase.

If temperature of the gas on reaching the combustion chamber is high enough for the gas to burn, then the gas inside the combustion chamber would burn before the ignition of the spark plug. This phenomena is called Knocking. Knocking can seriously damage an engine!

External Combustion Engine

An external combustion engine (EC engine) is a heat engine where an (internal) working fluid is heated by combustion of an external source, through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine produces motion and usable work. The fluid is then cooled, compressed and reused (closed cycle), or (less commonly) dumped, and cool fluid pulled in (open cycle air engine).

"Combustion" refers to burning fuel with an oxidizer, to supply the heat. Engines of similar (or even identical) configuration and operation may use a supply of heat from other sources such as nuclear, solar, geothermal or exothermic reactions not involving combustion; but are not then strictly classed as external combustion engines, but as external thermal engines.

|

| Diagram showing External Combustion Engine's Working |

"Combustion" refers to burning fuel with an oxidizer, to supply the heat. Engines of similar (or even identical) configuration and operation may use a supply of heat from other sources such as nuclear, solar, geothermal or exothermic reactions not involving combustion; but are not then strictly classed as external combustion engines, but as external thermal engines.

Oct 11, 2010

Posted by Sayantan Mandal

How Diesel Engine Work

One of the frequently asked questions to me from numerous people was "How diesel engine differs from a gasoline engine"

Both are internal combustion engine, both of them run on a 4-stroke cycle known as Otto-cycle, both convert chemical energy of fuel to mechanical energy by a series of small explosion in large number. So what's the basic difference, huh. The basic difference lies in the way fuel is induced in both the engine's cylinder. For better understanding of Diesel engine, do read our "How gasoline engine works" or 4-stroke engine works section and come back fast because now unfolding the biggest mystery of engineering that How Diesel Engine Work.

Technically, the difference between these engine lies in their Intake Stroke and Compression Stroke. In diesel only air is induced into the cylinder during Intake Stroke. Now piston moves up and compression stroke begins, this compresses the present air in the cylinder. The temperature of the air increases because on compressing or on reducing its volume the temperature of the air increases. Once the piston reaches the top or compresses the air fully, fuel is induced in the system. The temperature of the cylinder or system is high enough to ignite the fuel sprayed. An explosion occurs or Combustion Stroke begins this drives the piston back and after-that emission Stroke Occurs.

Diesel engine too have a 4-stroke cycle. These are:

Everyone has its pros and cons. Let's talk about the advantages and disadvantages of a diesel engine.

Pros

Both are internal combustion engine, both of them run on a 4-stroke cycle known as Otto-cycle, both convert chemical energy of fuel to mechanical energy by a series of small explosion in large number. So what's the basic difference, huh. The basic difference lies in the way fuel is induced in both the engine's cylinder. For better understanding of Diesel engine, do read our "How gasoline engine works" or 4-stroke engine works section and come back fast because now unfolding the biggest mystery of engineering that How Diesel Engine Work.

Technically, the difference between these engine lies in their Intake Stroke and Compression Stroke. In diesel only air is induced into the cylinder during Intake Stroke. Now piston moves up and compression stroke begins, this compresses the present air in the cylinder. The temperature of the air increases because on compressing or on reducing its volume the temperature of the air increases. Once the piston reaches the top or compresses the air fully, fuel is induced in the system. The temperature of the cylinder or system is high enough to ignite the fuel sprayed. An explosion occurs or Combustion Stroke begins this drives the piston back and after-that emission Stroke Occurs.

Diesel engine too have a 4-stroke cycle. These are:

- Intake stroke-Air is induced in the cylinder via intake port or pipe.

- Compression Stroke- Now the air present is compressed in order to increase the temperature of the air and also of the system.

- Combustion Stroke- Once the piston has completed the combustion stroke, fuel is introduced in which explodes due to high temperature of the system. This drives the piston back and hence combustion stroke comes into play.

- Emission Stroke-Now the piston comes back to remove the waste gases via exhaust port.

Everyone has its pros and cons. Let's talk about the advantages and disadvantages of a diesel engine.

Pros

- Highly fuel efficient engine. Have a greater mileage than that of gasoline engine

- Powerful boost. Diesel engine have less weight to compression ratio of cylinder and hence able to give much horsepower than a gasoline engine of its weight.

- Emit less CO2 and CO

- Produces sooty smoke, full of hydrocarbons leading to acid rain.

- It also generate nitrogenous compound which are very much harmful for the environment.

- These diesel engine has made their image like making clattering sound while moving. This is also posing a negative image on diesel engine while most of the gasoline engine don't produces much sound.

Oct 4, 2010

Posted by Sayantan Mandal

Secrets Behind NOS or Nitrous

When people talk about car race or racing games, the topic of NOS generally comes up. So actually what is NOS? How it Works?

Nos, Nitrous oxide (N2O) undergoes thermal decomposition and breaks up into Nitrogen and Oxygen, when heated at 300 degree C. Hence injection of NOS provides more oxygen during combustion. Technically, more oxygen in a cylinder means, more fuel can be induced in it leading to more power from that same engine. Hence a significant boost can be obtained from that same engine.

Moreover NOS also provides a cooling effect when it vaporizes. Specifically it absorbs the heat energy of the surroundings and vaporizes, leading to decline in temperature of intake pipe and the intake air. Hence due to less temperature of the air, volume of the air decreases and mass increases, or we can say that its density increases. Overall this all again leads to more availability of oxygen for combustion.

But there is only one major problem with Nitrous Oxide is that is very much bulky. A car needs a large amount of Nos, like any gas. Normally a 6 litre engine requires around 12,000 litre of air every minute running at 4,000 rpm, so it would need a tremendous amount of NOS to run a car continuously. So, a driver can only take a few minutes of NOS even after compressing it into liquid.

Moreover NOS also provides a cooling effect when it vaporizes. Specifically it absorbs the heat energy of the surroundings and vaporizes, leading to decline in temperature of intake pipe and the intake air. Hence due to less temperature of the air, volume of the air decreases and mass increases, or we can say that its density increases. Overall this all again leads to more availability of oxygen for combustion.

But there is only one major problem with Nitrous Oxide is that is very much bulky. A car needs a large amount of Nos, like any gas. Normally a 6 litre engine requires around 12,000 litre of air every minute running at 4,000 rpm, so it would need a tremendous amount of NOS to run a car continuously. So, a driver can only take a few minutes of NOS even after compressing it into liquid.

Oct 2, 2010

Posted by Sayantan Mandal

2-stroke engine vs 4-stroke engine

Advantages----

Disadvantages----

- 2-stroke engines have a significant power boost/supply than a 4-stroke engine as it is fired every 2 revolution and hence can produce double power than a 4-stroke engine.

- 2-stroke engine is lighter in weight due to simple construction than 4-stroke engine. as it don't have any mess with valves or we can say it don't have valves.

- A typical 4-stroke engine can't work in any orientation, in order to resolve it more complexities would be added to it. But in case of 2-stroke engine it will work in any orientation given.

- 2-stroke engines generate more power than 4-stroke engine

- Moreover 2-stroke engines are less expensive than 4-stroke engine.

Disadvantages----

- We all know that 2-stroke engine stroke engine require 4-stroke oil mixed with gas, in order to lubricate the crankshaft, It not only burns gas but also the 2-stroke engine oil with it.

- So 2-stroke engine oil adds to the cost of gas. Hence it becomes very much expensive.

- 2-stroke engines worn out very early than 4-stroke engines due to lack of dedicated lubricating system.

- Sometimes even gas leaks out of the exhaust valve of 2-stroke engine, leading to storage of gas.

- 2-stroke engine not uses the gas efficiently, leading to decrease in mileage of the system.

- 2-stroke engine produces a lot of pollution with it, leading to many environmental pollution.

Sep 29, 2010

Posted by Sayantan Mandal

Working of Two-Stroke Engine

Actually 2-stroke engine work in a very similar way to that of 4-stroke engine. Only there's a difference between the number of strokes or no. of cycles.

In a 2-stroke engine-

First-stroke:

The piston comes down and pressurizes the mixture of oil/air/gas upwards into the combustion chamber, this displaces the extra exhaust.

Now comes the most important stroke i.e. the Second stroke or Compression stroke:

Now the piston moves up, towards the spark plug this creates a vacuum in the crankcase and opens the inlet port & sucks the mixture into the crankcase from the carburetor. Here the piston compresses the mixture which it got in First stroke, the Spark plug ignites the mixture. This drives the piston back and the cycle continues....

See the Diagram while reading this would help you a lot.

In a four-stroke engine, there are separate intake, compression, combustion and exhaust strokes.

You can see here, intake and combustion is occurring at the same time, moreover instead of taking 4-stroke, it is burning the gas in just 2-stroke/cycles. These advantages make two-stroke engines lighter, simpler and less expensive to manufacture. Two-stroke engines also have the potential to pack about twice the power into the same space because there are twice as many power strokes per revolution. The combination of light weight and twice the power gives two-stroke engines a great power-to-weight ratio compared to many four-stroke engine designs.

In a 2-stroke engine-

|

| Demonstration Of Two Stroke Engine's Working |

First-stroke:

The piston comes down and pressurizes the mixture of oil/air/gas upwards into the combustion chamber, this displaces the extra exhaust.

Now comes the most important stroke i.e. the Second stroke or Compression stroke:

Now the piston moves up, towards the spark plug this creates a vacuum in the crankcase and opens the inlet port & sucks the mixture into the crankcase from the carburetor. Here the piston compresses the mixture which it got in First stroke, the Spark plug ignites the mixture. This drives the piston back and the cycle continues....

See the Diagram while reading this would help you a lot.

In a four-stroke engine, there are separate intake, compression, combustion and exhaust strokes.

You can see here, intake and combustion is occurring at the same time, moreover instead of taking 4-stroke, it is burning the gas in just 2-stroke/cycles. These advantages make two-stroke engines lighter, simpler and less expensive to manufacture. Two-stroke engines also have the potential to pack about twice the power into the same space because there are twice as many power strokes per revolution. The combination of light weight and twice the power gives two-stroke engines a great power-to-weight ratio compared to many four-stroke engine designs.

Sep 28, 2010

Posted by Sayantan Mandal

Working of Four-Stroke Engine

The biggest difference to notice when comparing figures between a 2-stroke engine and 4-stroke engine is that the spark-plug fires once every revolution in a two-stroke engine but in case of four-stroke engine the spark fires once every other revolution. First of all lets discuss about the working of four-stroke engine...

Today most of the cars use what is called Four-Stroke Combustion Cycle to convert gasoline into motion. The four-stroke approach is also known as the Otto cycle, in honor of Nikolaus Otto, who invented it in 1867. They are-

Step 1

The piston starts from the top, the intake valve is opened by the Camshaft, and the piston moves down to let the engine take in a cylinder-full of gasoline and air. Only the tiniest drop of gasoline needs to be mixed into the air for this to work.--------This all Process is called Intake Stroke.

Step 2

Then the piston moves back to compress this fuel & air mixture. This all makes the mixture more denser, internal temperature of the cylinder increases. Hence--------Compression Stroke makes the Explosion more powerful.

Step 3

And when the piston reaches the top of the cylinder, the spark plug emits a spark and ignites the gasoline. The gasoline charge in the cylinder explodes, driving the piston downwards.-------This is called as Combustion Stroke.

Step 4

Once the piston hits the bottom of its stroke, the exhaust valve opens and the exhaust leaves the cylinder to go out the tailpipe.-------This is called Exhaust Stroke.

Today most of the cars use what is called Four-Stroke Combustion Cycle to convert gasoline into motion. The four-stroke approach is also known as the Otto cycle, in honor of Nikolaus Otto, who invented it in 1867. They are-

- Intake Stroke

- Compression Stroke

- Combustion Stroke

- Exhaust Stroke

Working-

Step 1

The piston starts from the top, the intake valve is opened by the Camshaft, and the piston moves down to let the engine take in a cylinder-full of gasoline and air. Only the tiniest drop of gasoline needs to be mixed into the air for this to work.--------This all Process is called Intake Stroke.

Step 2

Then the piston moves back to compress this fuel & air mixture. This all makes the mixture more denser, internal temperature of the cylinder increases. Hence--------Compression Stroke makes the Explosion more powerful.

Step 3

And when the piston reaches the top of the cylinder, the spark plug emits a spark and ignites the gasoline. The gasoline charge in the cylinder explodes, driving the piston downwards.-------This is called as Combustion Stroke.

Step 4

Once the piston hits the bottom of its stroke, the exhaust valve opens and the exhaust leaves the cylinder to go out the tailpipe.-------This is called Exhaust Stroke.

Mar 25, 2010

Posted by Sayantan Mandal

Piston Engine Parts

Now you all know about different types of engines. Now let's start with the Internal Combustion engine's first part i.e. PISTON ENGINE.

Piston Engines are be classified further based on engine's cycle.... Ya, in case of Piston engine we have:

2 stroke engine

4 stroke engine

And, 6 stroke engine

But all of them has somewhat same kind of configuration. So before beginning the lesson let's get introduced with the parts it possesses

Spark Plug

The spark plug supplies the spark that ignites the air/fuel mixture so that combustion can occur. The spark must occur at right moment so that everything work properly.

Piston

Its a cylindrical piece of metal that moves up and down inside the combustion chamber

Crankshaft

When the piston is moved up and down, the converts that motion into a circular motion just like a crank on a jack-in-the-box does.

Valves

Its opens the space from where the mixture of air/fuel enters and the exhaust exits. Actually two valves are present one for the Intake and the other for Exhaust. Note-That both valves are closed during compression and combustion and therefore the combustion chamber is sealed for middle two stroke.

Connecting Rod

It connects the piston to the crankshaft. It can rotate at both ends so that its angle can change as the piston moves and the crankshaft rotates.

Sump

Its around the crankshaft and oil to lubricate the Connecting rod and the crankshaft.

Here's the original of DI-section of an Internal Combustion Engine:

Let start with -

4 stroke engine

Then we'll learn about 2 stroke engine

Then about the advantages & disadvantages between the above two

And, at last we'll see the working of 6 stroke engine

Piston Engines are be classified further based on engine's cycle.... Ya, in case of Piston engine we have:

But all of them has somewhat same kind of configuration. So before beginning the lesson let's get introduced with the parts it possesses

|

| Illustrated Diagram Of A BASIC Internal Combustion Engine |

Spark Plug

The spark plug supplies the spark that ignites the air/fuel mixture so that combustion can occur. The spark must occur at right moment so that everything work properly.

Piston

Its a cylindrical piece of metal that moves up and down inside the combustion chamber

Crankshaft

When the piston is moved up and down, the converts that motion into a circular motion just like a crank on a jack-in-the-box does.

Valves

Its opens the space from where the mixture of air/fuel enters and the exhaust exits. Actually two valves are present one for the Intake and the other for Exhaust. Note-That both valves are closed during compression and combustion and therefore the combustion chamber is sealed for middle two stroke.

Connecting Rod

It connects the piston to the crankshaft. It can rotate at both ends so that its angle can change as the piston moves and the crankshaft rotates.

Sump

Its around the crankshaft and oil to lubricate the Connecting rod and the crankshaft.

Here's the original of DI-section of an Internal Combustion Engine:

|

| Di-section Pic OF Internal Combustion Engine |

Let start with -

Mar 24, 2010

Posted by Sayantan Mandal

Internal Combustion Engine

Actually the basic concept behind an Internal Combustion Engine to be called as an Internal Combustion Engine is that the fuel which is available to it is burned inside the core of the engine or in other words the combustion process is carried out internally inside the box of the engine...

The basic principle behind any Internal Combustion Engine-

If you put a tiny amount of high-energy fuel (like gasoline) in a small, enclosed space and ignite it, an incredible amount of energy is released in the form of expanding gas. This large amount of energy can be used to propel a potato to a height of 500 feet. You can also use it for more interesting purposes. Then just think about it, if you can harness this incredible amount of energy in a useful way & could be able to create a cycle that allows you to set off explosions like this hundreds of times per minute, then we have is the basic core of an engine!!!

In fact there are many types of internal combustion engines available today, which uses various different methods to burn the fuel inside the engine. They are based on engine configuration:

|

| Di-section Of An Piston Engine |

The basic principle behind any Internal Combustion Engine-

If you put a tiny amount of high-energy fuel (like gasoline) in a small, enclosed space and ignite it, an incredible amount of energy is released in the form of expanding gas. This large amount of energy can be used to propel a potato to a height of 500 feet. You can also use it for more interesting purposes. Then just think about it, if you can harness this incredible amount of energy in a useful way & could be able to create a cycle that allows you to set off explosions like this hundreds of times per minute, then we have is the basic core of an engine!!!

In fact there are many types of internal combustion engines available today, which uses various different methods to burn the fuel inside the engine. They are based on engine configuration:

- Piston Engines - Piston Engines are classified further based on engine's cycle...

- Four Stroke Engines - Fuel is burned in 4 stroke of the piston i.e. two times ups and two times downs, with spark every other revolution.

- Two Stroke engines - Fuel is burned in a single revolution i.e. in 2 stroke, one up and one down, with spark every revolution.

- Diesel Engines - Here fuel is also burned in 4 stroke of the piston but without the spark, Yes!!! it doesn't have a spark plug in it. Fuel is burned using internal heat of the cylinder during compression.

- Wankel Engine

- Turbines

Getting confused?!!

Why don't get back and have a brief info about the Classification Of Engine......

Shaft Engine

Shaft engines are those kind of engines which transmits its rotatory power or torque using a Drive Shaft. Drive Shaft are subject to torsion and shear stress.

Drive Shaft has a great history....

Do you remember the old steam locomotives, they used to have a long steel rod mounted on the wheels of the steam engine. It used to slide length-wise and varying its length effectively. Ya, its a kind of drive shaft (as shown in pic) called 'quill drives'.

I remember when i used to go to school, i often see a rotating cylindrical rod beneath a truck. I used to think how this rotating rod is moving the wheels of the truck. Actually that rotating rod is noting but a Drive shaft which is transmitting the power to the wheels.

The above pic shows a pickup truck with 4 wheel drive. You can see two shaft in front of the power assembly which is driving the front tyres.

So all this is Drive Shaft all about....

Now Shaft Engines are of two Types:

Drive Shaft has a great history....

Do you remember the old steam locomotives, they used to have a long steel rod mounted on the wheels of the steam engine. It used to slide length-wise and varying its length effectively. Ya, its a kind of drive shaft (as shown in pic) called 'quill drives'.

|

| Photo Courtesy TijsB |

I remember when i used to go to school, i often see a rotating cylindrical rod beneath a truck. I used to think how this rotating rod is moving the wheels of the truck. Actually that rotating rod is noting but a Drive shaft which is transmitting the power to the wheels.

|

| Photo Courtesy troymckaskle |

So all this is Drive Shaft all about....

Now Shaft Engines are of two Types:

Mar 23, 2010

Posted by Sayantan Mandal

Classification of Engines

Have u ever wondered how a BMW run/races around tracks & streets just using gasoline (which we commonly say petrol). You might have heard things like "V-10 engines" and "dual overhead cams" and "triple fuel injection." But what does all this mean?

Many of you simply out of curiosity want to know and understand what actually is going on behind the big confusing jumble of metal, tubes and wires.

To be straight, the purpose of a gasoline car engine is to convert gasoline into motion. Actually the car burns the gasoline inside its engine. Therefore, a car engine is an internal combustion engine -- as combustion takes place internally inside.

There are typically three types of engines-

- Shaft Engines - These are the engines where power is transmitted (usually torque produced by engine) using a Drive Shaft.

- Internal Combustion Engine - Here gasoline is burned inside an engine. They are much better and gives good performance and are also very efficient than External Combustion Engine. There are different kinds of Internal Combustion Engine:

- Piston engine

- Wankel engine

- Turbines:

- Turboprop

- Turboshaft

|

| Photo Courtesy TheCarShooters |

- External Combustion Engine - A steam engines and steam boats are a good example of External combustion engine. The fuel (coal, wood, oil, whatever) in a steam engine burns outside the engine to create steam, and the steam creates motion inside the engine. These engines are very much heavy and bulky than Internal combustion engine.

|

| Steam Engine |

- Reaction Engines - Such engines are based on the Newton's third Law of Motion i.e. "For every action force there is an equal, but opposite, reaction force". Such engines provides a thrust which propelles the mass/ body forward by throwing out gases at high speed or we can say reaction mass.

- Tubines

- Turbojet

- Turbofan

- Propfan

- Rocket-powered

- Motorjet

- Pulsejet

- Ramjet

- Scramjet

- Other Type of Engines - These are miscellaneous engines, whose working is fuel by different Working Substance.

- Human-powered

- Electric

- Nuclear

- Hydrogen

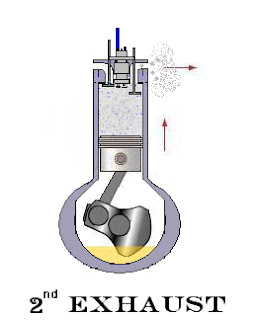

How Heat Engine Works

Do you know that a BMW car engine or its aircraft engine is actually a heat engine. Before we get into various combustion engine lets get into the basics, the building blocks of an ENGINE. It all starts with the concepts of thermodynamics,

In Thermodynamics, Heat Engine is a device by which a system is made to undergo a cyclic process that results in conversion of of heat or thermal energy to mechanical work..

Lets think the way Carnot thought, which leaded to the the invention of the car engine:

And its efficiency,

In Thermodynamics, Heat Engine is a device by which a system is made to undergo a cyclic process that results in conversion of of heat or thermal energy to mechanical work..

Lets think the way Carnot thought, which leaded to the the invention of the car engine:

Lets the circle in the middle be an engine and the box at the right be an external HOT reservoir and at the left be an external COLD reservoir:

- It consists of a working substance - the system. For example, a mixture of fuel vapor and air in a gasoline or a diesel engine or steam in steam engine are the working substance.

- The working substance goes through a cycle consisting of several processes. In some of these processes, it absorbs a total amount of heat QH from an external reservoir at some external temperature TH.

- In some other processes of the cycle, the working substance releases a total amount of heat QC to an external reservoir at some lower temperature TC.

- The work done (W) by the system in a cycle is transferred to the environment via some arrangement(e.g. the working substance may be in a cylinder with a moving piston that transfers mechanical energy to the wheels of a vehicle via a shaft).

Actually the engine is taking heat energy from hot reservoir releasing it to cold reservoir and delivers work W to the surrounding.

And its efficiency,

The cycle repeats itself again and again to get useful work......

For more info you can always refer to wikipedia, Here's the LINK: Heat Engine